Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Selecting the right hot stamping foil is crucial for achieving optimal results in your finishing project. The wrong choice can lead to poor adhesion, inconsistent appearance, or production problems. This guide will help you navigate the selection process with confidence.

Understanding Foil Construction

Hot stamping foils consist of multiple layers, each serving a specific function:

Carrier Film: The base layer (usually polyester) that supports the other components

Release Layer: Allows clean separation from the carrier during stamping

Lacquer Layer: Provides surface protection and gloss characteristics

Metallic or Pigment Layer: Creates the visual effect

Adhesive Layer: Bonds the foil to the substrate

Substrate Considerations

Paper and Cardboard – Standard metallics work well on coated papers – Use high-tack formulations for uncoated or textured stocks – Consider specialty adhesives for recycled content papers

Plastics – Match foil chemistry to plastic type (PP, PE, PVC, etc.) – Pre-treatment may be required for low surface energy plastics – Test adhesion thoroughly before production

Leather and Faux Leather – Use flexible formulations that won’t crack with material movement – Lower stamping temperatures prevent substrate damage – Matte finishes often work better than high-gloss on textured leathers

Fabric and Textiles – Specialized textile foils with flexible adhesive systems required – Consider wash resistance requirements – Test on actual production materials

Temperature and Pressure Optimization

Each foil type has optimal stamping parameters:

Standard Metallics: 100-120°C, medium pressure

Holographics: 90-110°C, light to medium pressure

Pigmented Foils: 110-130°C, medium to heavy pressure

Textile Foils: 130-160°C, heavy pressure

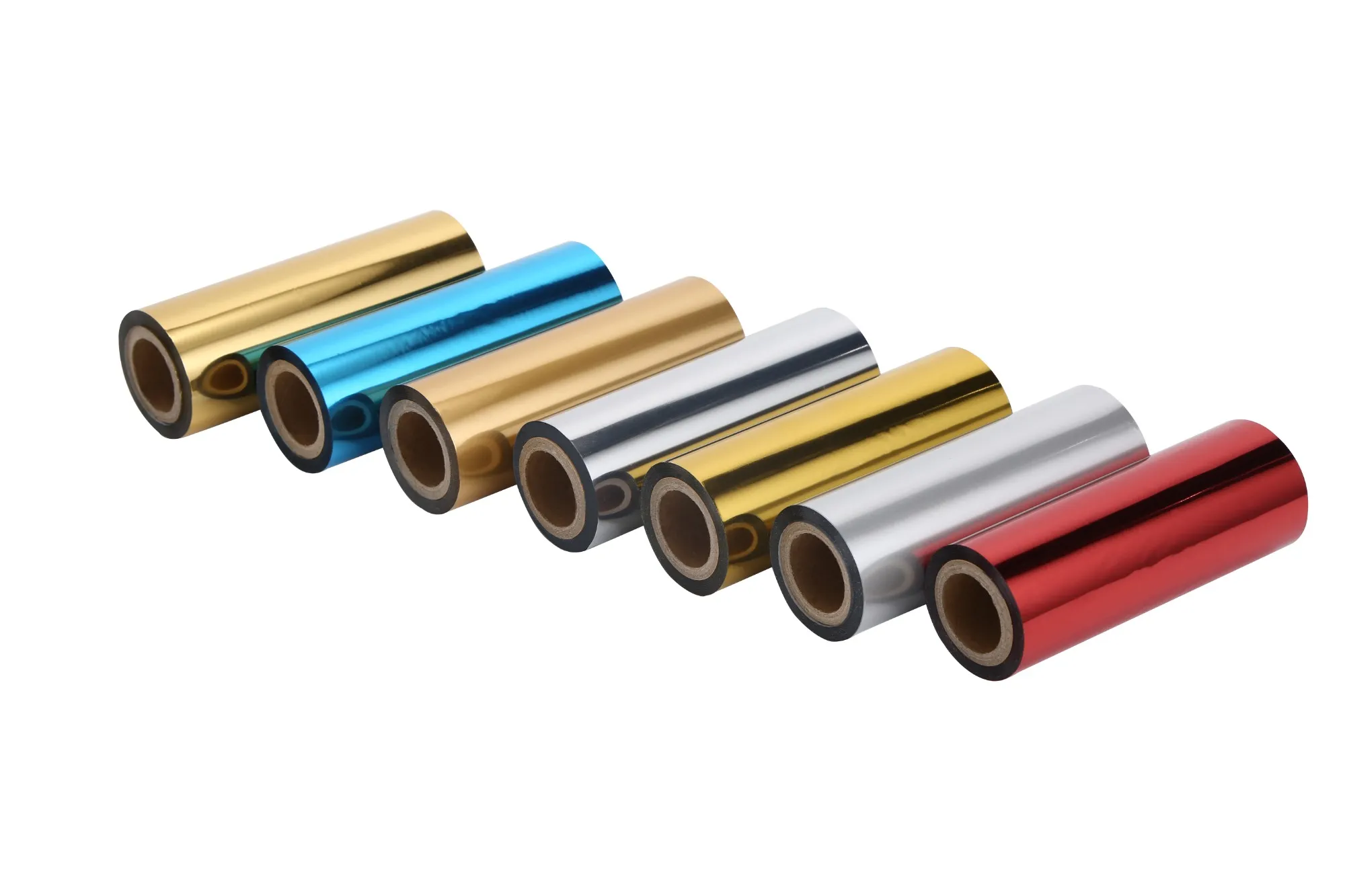

Color Selection Guidelines

Request physical samples in your actual substrate

Consider viewing conditions (retail lighting, outdoor, etc.)

Evaluate color against competing products on shelf

Account for substrate color showing through transparent foils

Testing Protocol

Before committing to production, conduct thorough testing:

Adhesion testing (tape pull, scratch resistance)

Environmental exposure (heat, cold, humidity)

Chemical resistance if applicable

Accelerated aging simulation

Production speed trials